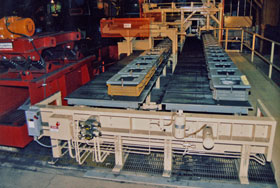

Mold Handling - Two Molds per Car

Summit Foundry Systems custom engineers, manufactures and installs mold handling systems that are built to withstand years of harsh foundry abuse. Equipment Components and Fabrication are sized for our "400 Series" to provide cost effective superior performance in Non-ferrous facilities or sized for our "500 Series" to survive the tougher operating conditions associated with Ferrous facilities. Mold handling systems are engineered to operate with all matchplate molding machines; Disa, Sinto, Hunter, B&P to name a few.

Two molds per car mold handling systems will operate at rates up to 160 molds per hour with "Smart Start" Control and can be configured to meet your cooling time requirements, work flow patterns and floor configurations. Options include two (2) cooling times; quick dump and full cooling, weight & jacket cleaning, mold rotation, jacket push down, and mold shuttling to overcome elevation and ergonomic constraints.

|

|

Appleton Electric |

Benton Foundry |

|

|

Denton Castings |

Dexter Company |

|

|

Epcor Foundries |

Galesburg Castings |

|

|

Wisconsin Aluminum |

|